评论 (0)

最近发表的文章

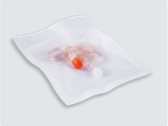

The Critical Role of Specification Data Management in Medical Device Packaging

Matthew Wright

教育

医疗器械

— 2 分钟阅读

联系我们

联系我们

CHAT